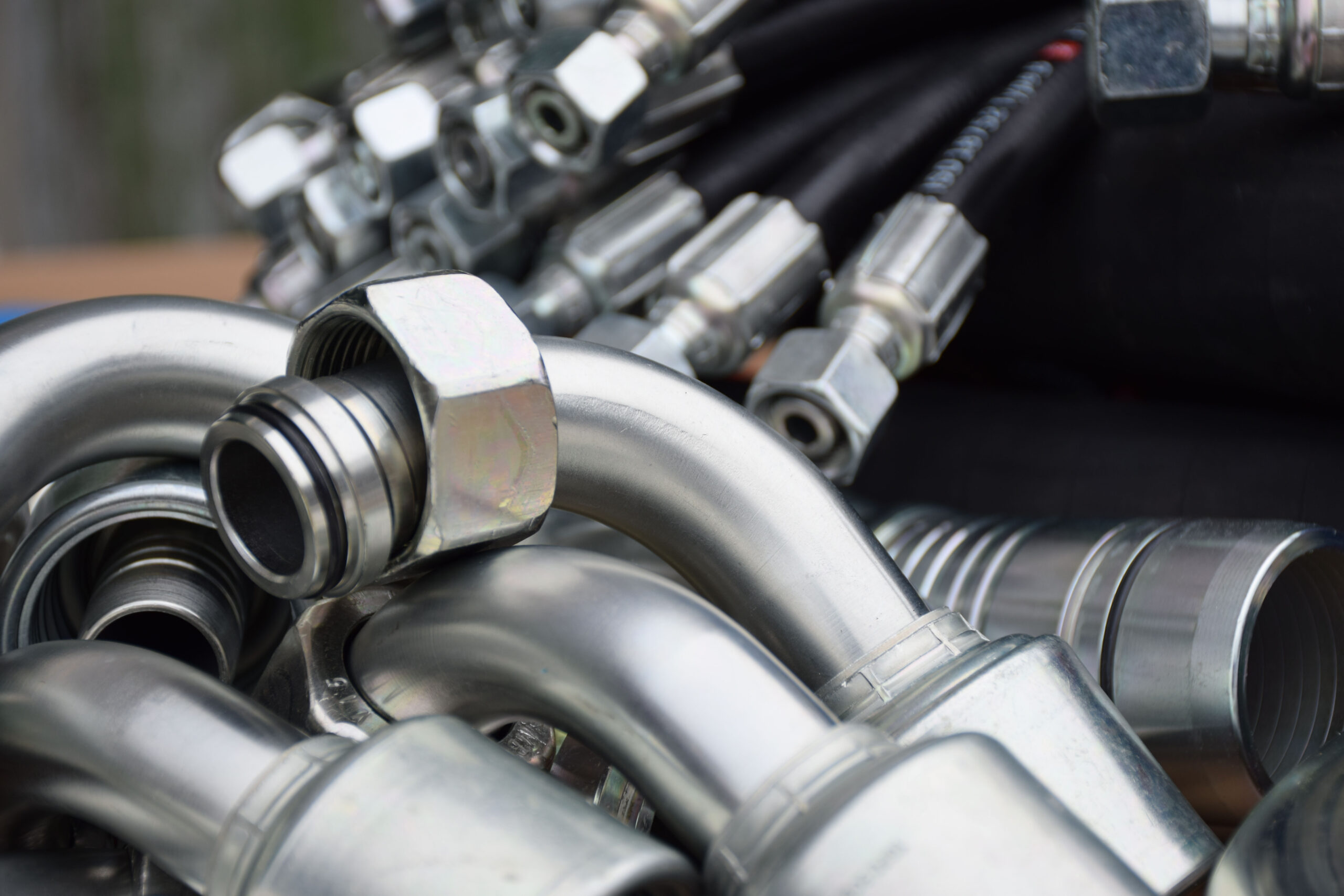

Using a metal hose is the best option for indoor washing machines, outdoor gardening equipment, and more. They’re incredibly durable and can last for about 8.7 years, according to Saginaw Bay Underwriters. Metal hoses have quite a lifespan compared to rubber ones, which is one reason why many homeowners are making the switch. Unfortunately, not all metal hoses are foolproof. Below are three of the most common signs that indicate your metal hose is damaged and needs to be replaced immediately.

1. Leaks Near Drain Openings

A metal hose is commonly used to connect indoor washing machines to a water supply. They’re designed to prevent leaks and flooding. However, if your hose leaks at a connection site, it’s best to replace it. Leaks might indicate that the entire hose is compromised, which can be disastrous and lead to flooding. It’s better to replace the hose than take a chance if you find a leak.

2. Kinks and Deformities

Unlike rubber, metal hoses are designed to withstand stress and can be used in all kinds of industries. If you notice any deformities in your product, it’s time to consider replacing them with newer ones. Deformities include kinks, bubbles, and frayed metal braids. These deformities usually occur with age but can also signify a manufacturer defect. In either case, replace the hose with a new one to ensure all water reaches your laundry machine and prevent flooding.

3. Damaged Attachments

The attachments on your metal hose should fit snugly onto the water delivery system or another pipe fitting. Replace a metal hose if these attachments are loose or damaged. One sign that an attachment is damaged is if water leaks out when you shut the hose on or off. Large spurts usually occur due to increased pressure near the attachment. Fortunately, you can fix most attachment issues by using a simple washer. All you have to do is replace the cracked washer within the attachment. However, if this doesn’t solve the issue, consider purchasing a new metal hose with different attachments.

A metal hose is one of the most durable products on the market. However, they can still be prone to damage, wear and tear, and manufacturer defects. Remember the above tips and conduct regular inspections on your metal hoses. Contact Universal Metal Hose for all your metal hose needs!